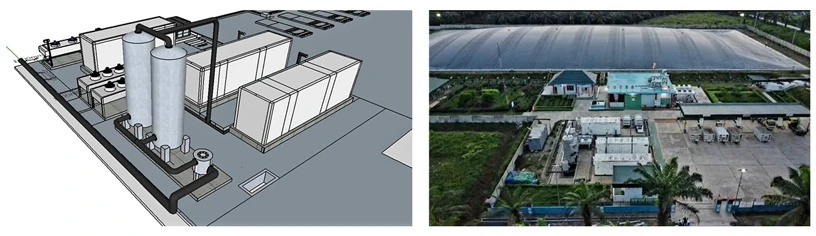

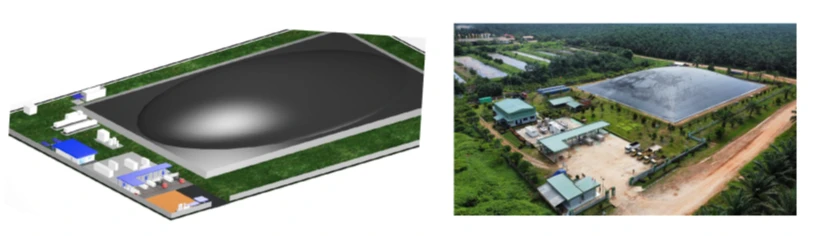

Raja Gas Kharisma (“RGK”), a sister company of PT. Raja Rafa Samudra (“RRS”), was awarded to design and construct the first ever Compressed Biomethane Gas (“Bio-CNG” or “CBG”) Plant in Indonesia. The first Bio-CNG Plant started construction in early 2019 and commissioned on August 2020.

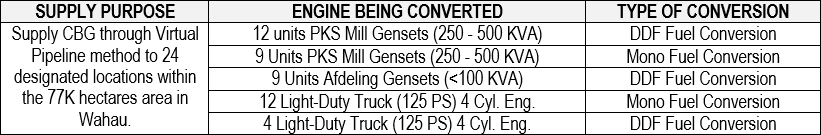

The plant itself was design for Twofold purpose; first to generate 1.2 MW of electricity to cover its Palm Oil Mill (POM) deficiency in electricity, and secondly producing 300 Nm³/hour to replace the diesel fuel consumed by many of its diesel generator sets spread across their 77 hectares plantation and its diesel fuel consumed by their FFB trucks.

Although construction of biogas facility to generate electricity has been much common in Indonesia, the fact that not only the upgrading technology from biogas in to Biomethane Compressed Gas (“CBG” or “Bio-CNG”) was ever done in Indonesia before, but also utilizing the CBG as a diesel substitute fuel also never been done in Indonesia or probably most part of the world. The success of the Bio-CNG1 POME waste to a renewable clean energy source for the plantation had led to a second Bio-CNG project that was commissioned in 2023.

This second Bio-CNG Plant was twice the capacity of the first one as it utilize the POME waste from two POME combined together generating 1.8 MW and an additional 650 Nm³/hour of CBG. Overall, from the two Bio-CNG Plant, it has generated a combine 3 MW electricity supply for its POMs, and an additional 950 Nm³ per hour or approximately 22,800 Nm³ per day or that leads to a potential 8.2 million of Nm³ per year. This is equivalent to 7.1 million of diesel liter equivalent substitution.

Having RRS, the holding company, expertise and a decade experience in the CNG business, that includes design and construction of CNG Facilities, CNG Distribution equipment, and Diesel to CNG Conversion, had made a true end-to-end waste to energy project can realized and successful.

For DSN, as the owner and beneficial of the project, not only had saved billions of Rupiah per year from substituting its diesel cost, which yearly had previously consumed more than 4 million liters diesel at an average price of Rp. 13.000 / liter, but also had made its global green company recognition both domestically and internationally and had made its CPO sale more welcome penetrating to the export market.