Provided that Biogas being captured in a contained storage and then has gone to an upgrading process whereby the biogas is being filtered to reach a low level of sulfur (S) to below 10 ppm, and low level of carbon dioxide (CO2) to lower than 10%, this biogas can then be considered similar or reach a standard level with the natural gas composition commercialized by the Oil & Gas Company in Indonesia.

Energy Table

FUEL TYPE | UNITS | HEATING VALUE | |

BTU/UNIT | KCAL/UNIT | ||

KEROSENE | Liter | 35,079 | 8,840 |

GASOLINE | Liter | 33,000 | 8,316 |

HSD | Liter | 35,964 | 9,063 |

MFO | Liter | 36,786 | 9,270 |

HFO | Liter | 38,754 | 9,766 |

LPG | Kg | 44,524 | 11,220 |

METHANE/NG | 37,073 | 8,986 | |

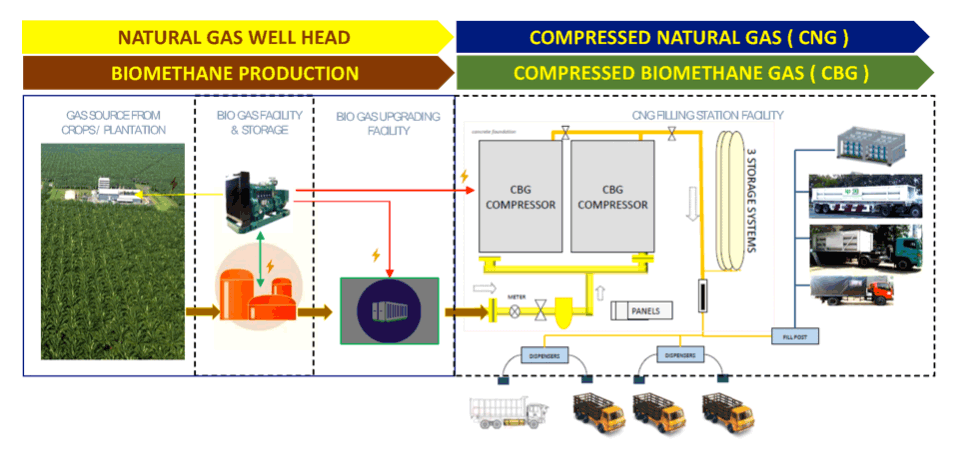

As the “upgraded” Biogas or biomethane is produced, it will need to be delivered to designated user of the biogas. Biomethane can be delivered to the end users through 3 (three) medium forms of distribution, which are through pipeline gas (PIPE), compressed biomethane gas (CBG), and even through a liquidation biomethane process (LBG). The most common ways thus far in Indonesia are through pipeline, even for the raw biogas itself. However, in some cases, delivery or even storing the biogas or biomethane becomes not feasibly possible, another way, in which RRS Group has been the pioneer in applying this technology in Indonesia, is through compressing the biomethane or CBG.

CBG itself is made by compressing the biomethane gas in a gas compressing facility called CBG Filling Station, which consist of several machinery equipment (primarily compressor) and piping installation (primarily to the filling dispenser), and then filled in to a hard-specialized container called cylinders tank at an average pressure of 200 – 250 kg/m2 (bar). The CBG filled to cylinder tank can either be filled directly for automotive fuel consumption or can be filled as storage to be then delivered through trucking fleets.